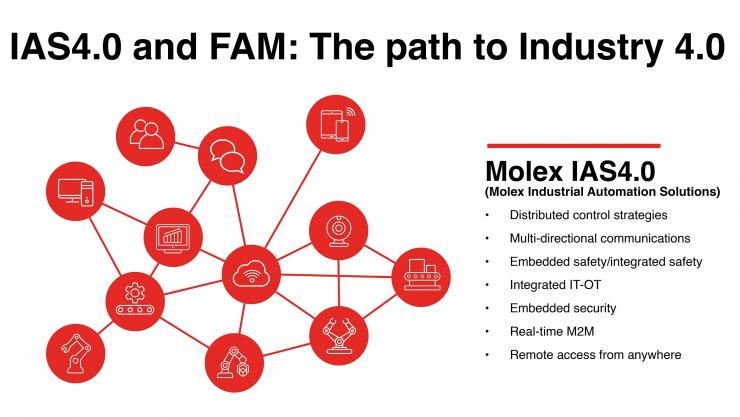

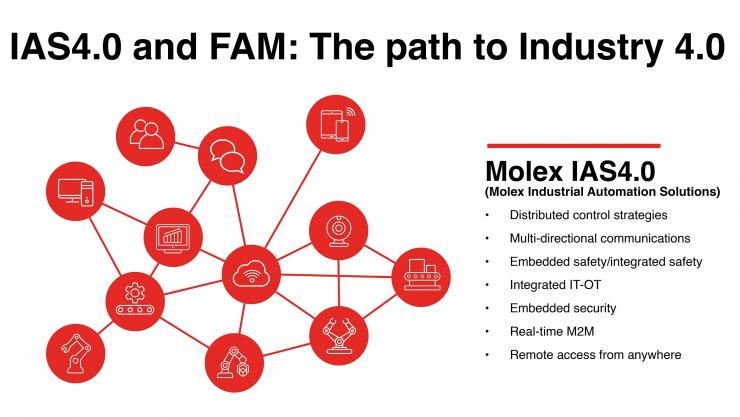

Molex Molex develops industrial automation solutions (IAS4.0) and new flexible automation modules (FAM) to accelerate the road to Industry 4.0

Keywords: Robot Molex Embedded

[Guide] Lyle, Illinois — July 28, 2021 — The global electronics industry leader and connectivity innovator Molex announced that it has made significant developments in continuing to promote Industry 4.0 and digital manufacturing initiatives.

· Modular FAM supports software-defined functions, and at the same time can be connected to the application of the Industrial Internet of Things IIoT to achieve agile, flexible and interconnected manufacturing

· Scalable, open and integrated industrial automation improves efficiency, reduces complexity and cost

· Manufacturers of robots, machines and equipment/control systems for the automotive, food and beverage, and material handling sectors will be the first to benefit

Lyle, Illinois — July 28, 2021 — Molex Molex, a global electronics industry leader and connectivity innovator, announced that it has made significant developments in continuing to promote Industry 4.0 and digital manufacturing initiatives. These developments and the introduction of Flexible Automation Modules (FAMs) have further expanded Molex's industrial automation solutions (IAS4.0), enabling stakeholders in the supply chain to build software-defined machines, robots and Production lines to meet the growing demand for interconnection, security, scalability and efficient operations.

John Newkirk, vice president and general manager of industrial solutions at Molex, said: "Traditional manufacturing systems lack flexibility, connectivity and distributed intelligence, and cannot effectively meet the rapidly changing market needs and consumer expectations. We are in the field of industrial automation. Traditional advantages, coupled with Molex's long-term relationship in the entire factory automation ecosystem, are driving the continuous development of open and modular IAS4.0 and FAM solutions, which significantly increase efficiency while reducing complexity , Cost and time to market."

According to the "State of Industry 4.0" survey conducted by Molex in June 2021, more than half of the respondents expect to achieve their Industry 4.0 goals within two years. However, almost all participants representing robots, machine/production lines and equipment or control system manufacturers have said they have encountered major technical challenges. The biggest obstacles include: independent IT and OT network infrastructure, restrictive communication protocols, limited remote access, uncoordinated cloud infrastructure and data solutions, and insufficient security capabilities.

FAM function provides unprecedented flexibility

As the core module of IAS4.0, FAM provides highly configurable and customizable connectivity, distributed control and Industrial Internet of Things (IIoT) applications to accelerate the development of flexible, modular and interconnected manufacturing machines. Pre-certified and customized FAM functions include distributed control, embedded security and assurance, multi-directional communication, configuration and device management, and remote configuration and programming services.

Critical manufacturing data can be collected and shared seamlessly from sensors or complex devices, between devices, machine-to-machine (M2M), or edge devices and the cloud. Feeding this data back to artificial intelligence (AI) and analytics solutions can help accelerate the realization of actionable insights. In addition, real-time data collection can help identify potential problems to improve predictive maintenance and reduce downtime, while at the same time ensuring effective decision-making through seamless integration with key business systems and services.

Eliminating manual steps and reducing hardware dependencies are expected to reduce overall costs, increase profit margins and flexibility to meet emerging digital manufacturing needs. The use of pre-certified and customized applications and libraries also helps equipment manufacturers speed up the development of individual machine control requirements, thereby shortening the design cycle.

The increasing degree of automation improves production efficiency

Molex IAS4.0 and FAM are very suitable for transforming the industrial automation supply chain in the automotive, food and beverage and material handling industries. By reducing reliance on hardware, manufacturers can reconfigure production lines to support the manufacture of customized products. Take the automotive industry as an example. This technology allows different models to be produced on the same production line while automatically converting different functions and decorations. As the availability of materials and components changes, it improves the flexibility of the supply chain.

For manufacturers of complex machines and production lines, Molex IAS4.0 solutions include software-driven FAM distributed control and embedded functional safety, which can reduce overall cabinet requirements. With the transition to a more flexible architecture, industrial automation stakeholders can advance their digital manufacturing strategy while improving production line innovation and operational efficiency.

Future applications of Molex's advanced industrial automation solutions include: deployment of enhanced IP67 devices, which simplify wiring while improving reusability and portability; deployment of advanced sensors required for collaborative robots, such as motion safety; and automatic or Zero-touch service and asset management service for updating equipment, machines and systems on demand.